減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji)主要是用來(lai)降低轉(zhuan)(zhuan)速(su)(su)(su)(su)和(he)增大轉(zhuan)(zhuan)矩,以滿足(zu)工作要求。減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji)的(de)(de)種類很多,其(qi)種類的(de)(de)分(fen)(fen)(fen)(fen)類可(ke)按(an)傳動的(de)(de)類型和(he)齒輪(lun)(lun)(lun)的(de)(de)外形以及傳動的(de)(de)級(ji)數(shu)等來(lai)分(fen)(fen)(fen)(fen),按(an)傳動類型來(lai)分(fen)(fen)(fen)(fen)時,可(ke)分(fen)(fen)(fen)(fen)為齒輪(lun)(lun)(lun)減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji),蝸(gua)桿減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji)和(he)行星齒輪(lun)(lun)(lun)減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji)以及由齒輪(lun)(lun)(lun)和(he)蝸(gua)桿相互(hu)組(zu)合(he)起來(lai)的(de)(de)減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji)。按(an)照(zhao)齒輪(lun)(lun)(lun)的(de)(de)外形來(lai)分(fen)(fen)(fen)(fen),可(ke)分(fen)(fen)(fen)(fen)為圓(yuan)柱齒輪(lun)(lun)(lun)減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji),圓(yuan)錐(zhui)(zhui)齒輪(lun)(lun)(lun)減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji)和(he)圓(yuan)錐(zhui)(zhui)—圓(yuan)柱齒輪(lun)(lun)(lun)減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji)。當按(an)照(zhao)傳動的(de)(de)級(ji)數(shu)來(lai)分(fen)(fen)(fen)(fen)時,可(ke)分(fen)(fen)(fen)(fen)為單級(ji)減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji)和(he)多級(ji)減(jian)(jian)(jian)速(su)(su)(su)(su)電(dian)(dian)(dian)機(ji)(ji)(ji)。

齒(chi)(chi)(chi)輪和蝸桿組成的常用的減(jian)(jian)速(su)電機(ji)(ji)(ji)主要有(you)齒(chi)(chi)(chi)輪減(jian)(jian)速(su)電機(ji)(ji)(ji),蝸桿減(jian)(jian)速(su)電機(ji)(ji)(ji),蝸桿—齒(chi)(chi)(chi)輪減(jian)(jian)速(su)電機(ji)(ji)(ji),行星齒(chi)(chi)(chi)輪減(jian)(jian)速(su)電機(ji)(ji)(ji),擺(bai)線針輪減(jian)(jian)速(su)電機(ji)(ji)(ji),諧波齒(chi)(chi)(chi)輪減(jian)(jian)速(su)電機(ji)(ji)(ji)等六種,而且這(zhe)六種減(jian)(jian)速(su)電機(ji)(ji)(ji)都已經有(you)系列產(chan)品,在選(xuan)型時只有(you)在找不(bu)到合適的產(chan)品時,才自行設計制造減(jian)(jian)速(su)電機(ji)(ji)(ji)。

常(chang)見的(de)減(jian)速電(dian)機的(de)特點介紹(shao):齒(chi)輪減(jian)速電(dian)機應(ying)用,結(jie)構(gou)(gou)(gou)簡(jian)單,精度容易,而且輪齒(chi)可做成直齒(chi)、斜齒(chi)和人字齒(chi)等。蝸(gua)桿減(jian)速電(dian)機結(jie)構(gou)(gou)(gou)緊湊,傳動(dong)比大(da),工作平(ping)穩(wen),噪音小,但是效(xiao)率比較低。蝸(gua)桿—齒(chi)輪減(jian)速電(dian)機有齒(chi)輪傳動(dong)在速級和蝸(gua)桿傳動(dong)在速級兩種形式,前者(zhe)的(de)結(jie)構(gou)(gou)(gou)緊湊,后者(zhe)的(de)傳動(dong)效(xiao)率。

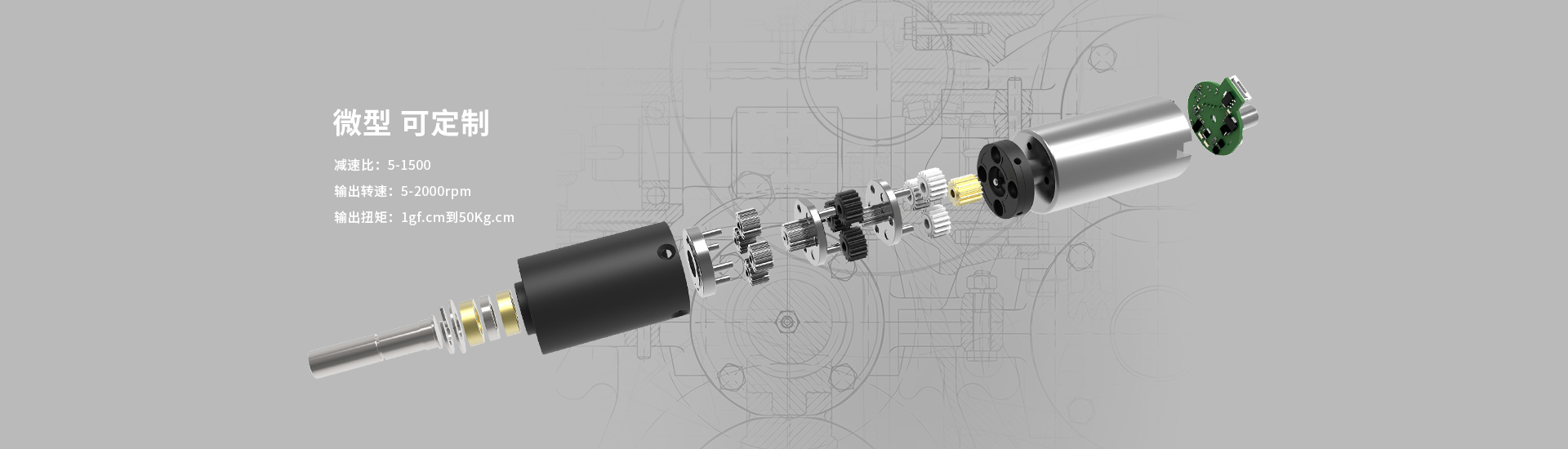

行(xing)星(xing)(xing)齒輪減速電(dian)(dian)機(ji)的行(xing)星(xing)(xing)齒輪傳動(dong)有效利(li)用(yong)了功率分流(liu)和輸入、輸出的同(tong)軸性以(yi)及合理(li)的使用(yong)了內嚙合,因(yin)而與普通(tong)定(ding)軸齒輪傳動(dong)相比較,行(xing)星(xing)(xing)齒輪減速電(dian)(dian)機(ji)具有質量小、體積(ji)小、傳動(dong)比大(da)、承載能(neng)力大(da)以(yi)及傳動(dong)平穩和傳動(dong)效率等(deng)特(te)點。行(xing)星(xing)(xing)齒輪減速電(dian)(dian)機(ji)因(yin)具有這些特(te)點,所以(yi)被的應用(yong)于冶金、礦山、建筑、航(hang)空等(deng)機(ji)械領域。

擺(bai)線針輪(lun)減(jian)速(su)(su)電(dian)機采用的(de)(de)(de)是(shi)(shi)少(shao)齒(chi)(chi)(chi)差(cha)(cha)行星傳動原理,其(qi)傳動過程是(shi)(shi)在輸入軸(zhou)上(shang)裝有一個錯位180度的(de)(de)(de)雙(shuang)偏(pian)心套,在偏(pian)心套上(shang)裝有兩個稱(cheng)為(wei)轉臂的(de)(de)(de)滾柱軸(zhou)承,形成H機構,兩個擺(bai)線輪(lun)的(de)(de)(de)中心孔(kong)即(ji)為(wei)偏(pian)心套,上(shang)傳臂軸(zhou)承的(de)(de)(de)滾道,并由擺(bai)線輪(lun)與針齒(chi)(chi)(chi)輪(lun)相嚙(nie)合,組(zu)成差(cha)(cha)為(wei)一齒(chi)(chi)(chi)的(de)(de)(de)內嚙(nie)合減(jian)速(su)(su)機構。諧(xie)波齒(chi)(chi)(chi)輪(lun)傳動是(shi)(shi)諧(xie)波齒(chi)(chi)(chi)輪(lun)行星傳動的(de)(de)(de)簡稱(cheng),諧(xie)波齒(chi)(chi)(chi)輪(lun)減(jian)速(su)(su)電(dian)機傳動是(shi)(shi)一種少(shao)齒(chi)(chi)(chi)差(cha)(cha)行星傳動,通常由剛性圓柱齒(chi)(chi)(chi)輪(lun),柔性圓柱齒(chi)(chi)(chi)輪(lun),波發生器和柔性軸(zhou)承等零件構成。

銷(xiao)售電話(hua):400-066-2287

郵箱(xiang):sales@szzhaowei.net

傳真(zhen):0755-27323949

郵編:518000

地址:深(shen)圳市(shi)寶安區燕(yan)羅街道燕(yan)川(chuan)社(she)區燕(yan)湖(hu)路(lu)62號