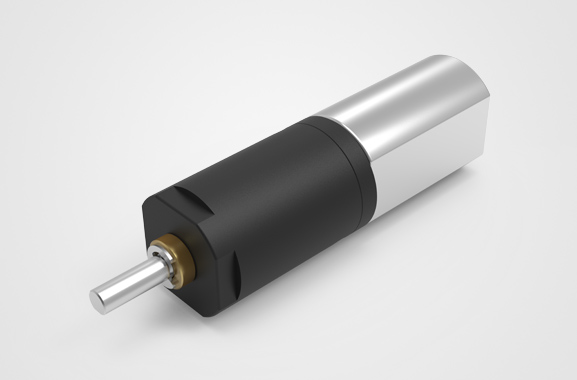

齒輪箱電機的齒輪制造

微型直流電機其具(ju)有速度,扭矩小的特點。接下來(lai)一起了解下吧。

滾(gun)刀(dao)(dao)滾(gun)削(xue)加(jia)工:微(wei)(wei)型齒輪(lun)在進行微(wei)(wei)加(jia)工時,由于齒形微(wei)(wei)小,除滾(gun)刀(dao)(dao)齒形誤差(cha)外,滾(gun)刀(dao)(dao)的孔徑跳動、端面跳動、周節等誤差(cha)都將(jiang)對微(wei)(wei)型齒輪(lun)的精度有很大的影(ying)響。而(er)加(jia)工用的滾(gun)齒機(ji),工件(jian)主軸等等諸多(duo)方面的因素都會影(ying)響微(wei)(wei)型齒輪(lun)的制造(zao)精度。在提制造(zao)系統總的綜合精度的基礎上,在選擇(ze)易切削(xue)的材料,就可較容易的實現批(pi)量生產模數相同(tong),品種(zhong)不同(tong)的微(wei)(wei)型齒輪(lun)。

注(zhu)(zhu)射成(cheng)(cheng)(cheng)(cheng)(cheng)型(xing)(xing)塑(su)料(liao)齒(chi)(chi)輪(lun)(lun)(lun)加工:利用(yong)(yong)注(zhu)(zhu)射成(cheng)(cheng)(cheng)(cheng)(cheng)型(xing)(xing)的(de)(de)(de)(de)方法來(lai)加工塑(su)料(liao)齒(chi)(chi)輪(lun)(lun)(lun),由于(yu)能在短(duan)時(shi)間(jian)內實現(xian)大批量生(sheng)產(chan)(chan),所(suo)以(yi)這(zhe)些注(zhu)(zhu)射成(cheng)(cheng)(cheng)(cheng)(cheng)型(xing)(xing)的(de)(de)(de)(de)齒(chi)(chi)輪(lun)(lun)(lun)多用(yong)(yong)于(yu)辦公室機器(qi),家用(yong)(yong)電器(qi)等較輕載荷下使(shi)(shi)用(yong)(yong)的(de)(de)(de)(de)齒(chi)(chi)輪(lun)(lun)(lun)。近(jin)年來(lai),在注(zhu)(zhu)射成(cheng)(cheng)(cheng)(cheng)(cheng)型(xing)(xing)技(ji)術不(bu)斷提,注(zhu)(zhu)射材料(liao)性能不(bu)斷改(gai)進(jin)的(de)(de)(de)(de)同(tong)時(shi),注(zhu)(zhu)射成(cheng)(cheng)(cheng)(cheng)(cheng)型(xing)(xing)齒(chi)(chi)輪(lun)(lun)(lun)的(de)(de)(de)(de)精(jing)度也大幅度的(de)(de)(de)(de)提,注(zhu)(zhu)射齒(chi)(chi)輪(lun)(lun)(lun)所(suo)用(yong)(yong)模具的(de)(de)(de)(de)精(jing)度和注(zhu)(zhu)射成(cheng)(cheng)(cheng)(cheng)(cheng)型(xing)(xing)技(ji)術均為(wei)英雄(xiong)注(zhu)(zhu)射成(cheng)(cheng)(cheng)(cheng)(cheng)型(xing)(xing)的(de)(de)(de)(de)重(zhong)要因(yin)素。同(tong)時(shi)注(zhu)(zhu)射成(cheng)(cheng)(cheng)(cheng)(cheng)型(xing)(xing)齒(chi)(chi)輪(lun)(lun)(lun)加工技(ji)術由于(yu)采用(yong)(yong)基準件,借助化學(xue)溶解法,可(ke)以(yi)加工出形狀復雜的(de)(de)(de)(de)模具來(lai),除(chu)了可(ke)以(yi)生(sheng)產(chan)(chan)出直齒(chi)(chi)輪(lun)(lun)(lun)、斜齒(chi)(chi)輪(lun)(lun)(lun)外,錐齒(chi)(chi)輪(lun)(lun)(lun),端面齒(chi)(chi)輪(lun)(lun)(lun),蝸桿,渦輪(lun)(lun)(lun)等各種不(bu)同(tong)類型(xing)(xing)的(de)(de)(de)(de)模具都能制造。使(shi)(shi)用(yong)(yong)精(jing)度模具,使(shi)(shi)塑(su)料(liao)微(wei)型(xing)(xing)齒(chi)(chi)輪(lun)(lun)(lun)的(de)(de)(de)(de)大規模生(sheng)產(chan)(chan)成(cheng)(cheng)(cheng)(cheng)(cheng)為(wei)可(ke)能。

金屬燒結制(zhi)作(zuo)法(fa):由于齒(chi)形微小,微型齒(chi)輪(lun)的(de)精(jing)加工比較困難,加之金屬粉末的(de)金屬可憐較大,從而限制(zhi)了其(qi)形狀的(de)精(jing)度和表面(mian)光潔度的(de)提。這是因為,模(mo)具成(cheng)型后,經過溫燒結,變形很大。

其他(ta)制造方法:今后微型齒輪(lun)的需求越來越多,新的制造方法和(he)批量(liang)生(sheng)產技術也將不斷(duan)出現。