機器人行星齒輪減速機科普介紹

機器人行星齒輪減速機是一種運用廣泛的減速傳動設備,行星齒輪減速機以其體積小,傳動效率高,減速范圍廣,精度高等諸多優點,而被廣泛應用于機器人傳動系統中,行星齒輪箱可以集成伺服電機、步進電機、直流電機使用。行星齒輪減速機因為結(jie)構原因,單級(ji)減(jian)速(su)(su)小為2.8,大(da)一(yi)般(ban)不超過12.5,常見減(jian)速(su)(su)比為:3/4/5/6/8/10,行星齒輪箱級(ji)數一(yi)般(ban)不超過3,但有部分(fen)大(da)減(jian)速(su)(su)比定制齒輪箱有4級(ji)減(jian)速(su)(su)。相(xiang)對其他減(jian)速(su)(su)機,行星齒輪減(jian)速(su)(su)機具有高剛性、高精度(單級(ji)可做到1分(fen)以內)、高傳動效率(單級(ji)在(zai)97%-98%)、高的(de)扭矩/體積比、終身(shen)免維護(hu)等(deng)特(te)點。

機器(qi)人(ren)(ren)行(xing)星(xing)(xing)(xing)(xing)齒(chi)輪(lun)減(jian)(jian)速(su)(su)機更是必不(bu)可(ke)少的(de)(de)零部件。與常(chang)規(gui)自動(dong)化(hua)設備(bei)用(yong)(yong)行(xing)星(xing)(xing)(xing)(xing)減(jian)(jian)速(su)(su)器(qi)有所不(bu)同,由于(yu)一般機器(qi)人(ren)(ren)在工(gong)作中(zhong)(zhong)會不(bu)斷執行(xing)重(zhong)復性動(dong)作,所以對于(yu)定位精(jing)度和重(zhong)復定位精(jing)度要(yao)求高,而且(qie)機器(qi)人(ren)(ren)、尤其是輕型機器(qi)人(ren)(ren)與大型自動(dong)化(hua)設備(bei)相比(bi)體積小(xiao)、重(zhong)量(liang)輕,因此(ci)作為(wei)零件,行(xing)星(xing)(xing)(xing)(xing)齒(chi)輪(lun)減(jian)(jian)速(su)(su)機也應當滿足輕量(liang)化(hua)的(de)(de)要(yao)求。目前運(yun)用(yong)(yong)機器(qi)人(ren)(ren)中(zhong)(zhong)的(de)(de)減(jian)(jian)速(su)(su)器(qi)主(zhu)要(yao)有:行(xing)星(xing)(xing)(xing)(xing)齒(chi)輪(lun)減(jian)(jian)速(su)(su)機(智能(neng)機器(qi)人(ren)(ren))、諧波(bo)減(jian)(jian)速(su)(su)器(qi)和RV減(jian)(jian)速(su)(su)器(qi)(關節機器(qi)人(ren)(ren))。行(xing)星(xing)(xing)(xing)(xing)顧(gu)名思義就是圍繞恒(heng)星(xing)(xing)(xing)(xing)轉動(dong),行(xing)星(xing)(xing)(xing)(xing)齒(chi)輪(lun)箱(xiang)有三個(ge)(ge)行(xing)星(xing)(xing)(xing)(xing)輪(lun)圍繞一個(ge)(ge)太(tai)陽輪(lun)旋轉,行(xing)星(xing)(xing)(xing)(xing)齒(chi)輪(lun)箱(xiang)體積小(xiao)、重(zhong)量(liang)輕,承載能(neng)力高,使用(yong)(yong)壽命長、運(yun)轉平(ping)穩,噪(zao)聲低。具有功(gong)率分流、多齒(chi)嚙合獨用(yong)(yong)的(de)(de)特性,廣泛應用(yong)(yong)于(yu)工(gong)業中(zhong)(zhong)。

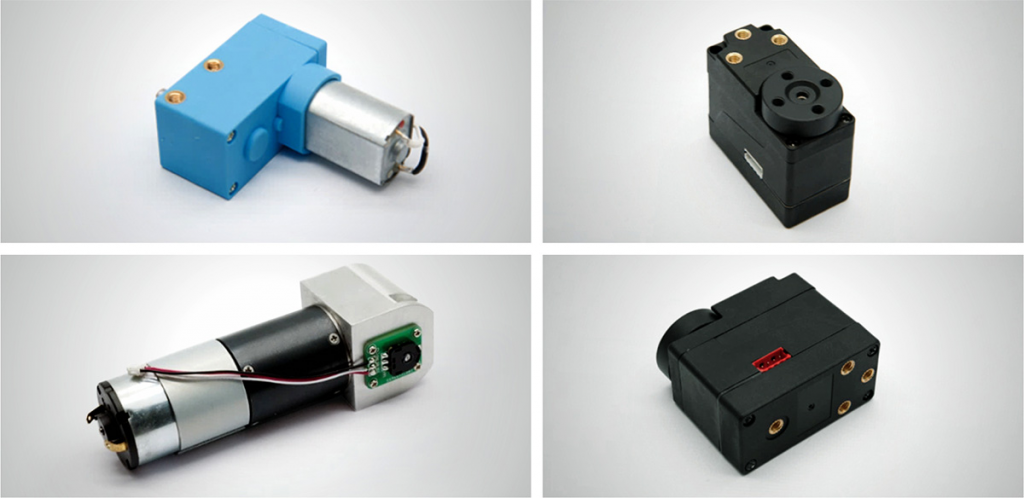

兆威(wei)機(ji)(ji)電公司研發(fa)(fa)的精密微型(xing)行(xing)(xing)星(xing)(xing)齒(chi)(chi)輪減(jian)速機(ji)(ji)技(ji)術參數范(fan)圍在(zai)直徑尺寸在(zai)8mm-38mm;齒(chi)(chi)輪箱(xiang)(xiang)材(cai)質分為塑膠齒(chi)(chi)輪、金(jin)屬齒(chi)(chi)輪;電壓(ya)在(zai)3V-24V之(zhi)間(jian);傳動(dong)噪音在(zai)45DB以下;減(jian)速比在(zai)5-1500;輸出轉速在(zai)5-2000rpm;輸出力矩:1gf-cm到(dao)50kgf-cm;傳動(dong)精度在(zai)1-2弧分內;同時也可以采用(yong)定制技(ji)術參數開(kai)發(fa)(fa)而成,例(li)如教育機(ji)(ji)器(qi)人(ren)(ren)行(xing)(xing)星(xing)(xing)齒(chi)(chi)輪箱(xiang)(xiang)、服(fu)務(wu)機(ji)(ji)器(qi)人(ren)(ren)行(xing)(xing)星(xing)(xing)齒(chi)(chi)輪箱(xiang)(xiang)、工業機(ji)(ji)器(qi)人(ren)(ren)行(xing)(xing)星(xing)(xing)齒(chi)(chi)輪箱(xiang)(xiang)、科(ke)研探險(xian)機(ji)(ji)器(qi)人(ren)(ren)行(xing)(xing)星(xing)(xing)齒(chi)(chi)輪箱(xiang)(xiang)、戶外機(ji)(ji)器(qi)人(ren)(ren)行(xing)(xing)星(xing)(xing)齒(chi)(chi)輪箱(xiang)(xiang)等。