微型減速電機的啟動方法

兆(zhao)威機(ji)(ji)電(dian)(dian)開發的齒(chi)輪箱(xiang)(xiang)減速(su)(su)(su)電(dian)(dian)機(ji)(ji)應用于汽車領(ling)域的:汽車儀(yi)表傳動(dong)減速(su)(su)(su)電(dian)(dian)機(ji)(ji),電(dian)(dian)動(dong)座椅減速(su)(su)(su)齒(chi)輪箱(xiang)(xiang),玻璃(li)升降器齒(chi)輪箱(xiang)(xiang)電(dian)(dian)機(ji)(ji),電(dian)(dian)動(dong)后視鏡減速(su)(su)(su)齒(chi)輪箱(xiang)(xiang),及(ji)家(jia)居(ju)(ju)用品:自動(dong)感應垃圾桶減速(su)(su)(su)齒(chi)輪箱(xiang)(xiang),榨汁機(ji)(ji)電(dian)(dian)機(ji)(ji),吸塵器電(dian)(dian)機(ji)(ji)以(yi)及(ji)各種(zhong)智(zhi)能家(jia)居(ju)(ju)電(dian)(dian)機(ji)(ji)等。

如何啟動微型減速電機呢?啟(qi)(qi)動設備(bei)也是一件有技術要求的事情,下(xia)面我就(jiu)給大家(jia)簡單(dan)介紹(shao)一下(xia)啟(qi)(qi)動微型電機的三種(zhong)方法:

1、直接起動

直接起(qi)動不需(xu)附加起(qi)動設備,操作簡便(bian),但主要(yao)缺(que)點(dian)是起(qi)動電流甚大,使(shi)電網受到電流沖擊,且使(shi)電機(ji)換向惡化;

2、降壓起動

用降低電(dian)深電(dian)壓的(de)方法來限制起動電(dian)流,這種起動方法適用于勵磁方式(shi)采用他(ta)勵的(de)微型(xing)電(dian)機,微型(xing)電(dian)機在(zai)起動過程(cheng)中起動平滑,消耗能少,但(dan)需配有專用電(dian)源設備;

3、電樞回路串聯電阻起動

在電(dian)(dian)(dian)樞回路內,起(qi)動(dong)電(dian)(dian)(dian)阻,以限制起(qi)動(dong)電(dian)(dian)(dian)流。起(qi)動(dong)電(dian)(dian)(dian)阻通常為一分(fen)級可變電(dian)(dian)(dian)阻,在起(qi)動(dong)過程(cheng)中逐級短接,這種起(qi)動(dong)方法應用(yong)于各種規格的微型電(dian)(dian)(dian)機,起(qi)動(dong)過程(cheng)中能母(mu)消耗較大,因此經常頻(pin)繁起(qi)動(dong)的大、中型電(dian)(dian)(dian)動(dong)機不宜采用(yong)。

上述的(de)(de)每一種方(fang)式都可以成(cheng)功的(de)(de)啟動微型電機,每一種方(fang)法(fa)都是各自的(de)(de)特點和不(bu)足,朋(peng)友(you)們可以根據(ju)自己的(de)(de)實際(ji)情況(kuang)來選擇合適的(de)(de)啟動方(fang)法(fa)!

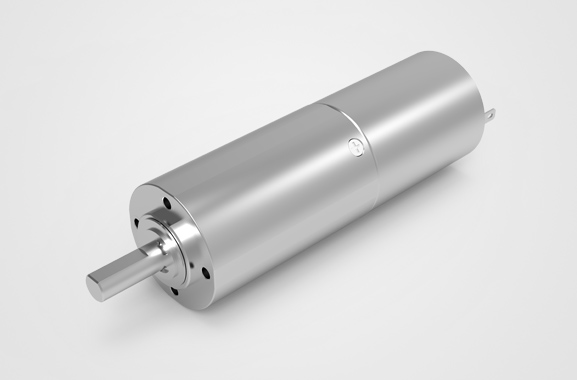

兆威機電擁有多年齒輪及齒輪箱領域設計、開發和生產經驗,并通過大量的實驗測試數據設計開發出減速齒輪箱,直流減速馬達,微(wei)型直流減(jian)速(su)電(dian)機(ji)(ji),行星減(jian)速(su)電(dian)機(ji)(ji),減(jian)速(su)電(dian)機(ji)(ji)馬達等產品。