有刷直流(liu)電動機是一種(zhong)運用(yong)廣泛(fan)的(de)直流(liu)電(dian)(dian)(dian)(dian)(dian)機(ji)傳動(dong)設(she)備(bei)(bei),在智能家居,家用(yong)電(dian)(dian)(dian)(dian)(dian)器,汽車傳動(dong),工業自動(dong)化,機(ji)器人設(she)備(bei)(bei),電(dian)(dian)(dian)(dian)(dian)子產品(pin),醫療器械設(she)備(bei)(bei)等(deng)領域;有刷(shua)電(dian)(dian)(dian)(dian)(dian)機(ji)的(de)定子上(shang)安裝(zhuang)有固定的(de)主磁極和電(dian)(dian)(dian)(dian)(dian)刷(shua),轉子上(shang)安裝(zhuang)有電(dian)(dian)(dian)(dian)(dian)樞(shu)繞(rao)組和換(huan)(huan)向(xiang)器。直流(liu)電(dian)(dian)(dian)(dian)(dian)源的(de)電(dian)(dian)(dian)(dian)(dian)能通(tong)過(guo)電(dian)(dian)(dian)(dian)(dian)刷(shua)和換(huan)(huan)向(xiang)器進入電(dian)(dian)(dian)(dian)(dian)樞(shu)繞(rao)組,產生(sheng)(sheng)電(dian)(dian)(dian)(dian)(dian)樞(shu)電(dian)(dian)(dian)(dian)(dian)流(liu),電(dian)(dian)(dian)(dian)(dian)樞(shu)電(dian)(dian)(dian)(dian)(dian)流(liu)產生(sheng)(sheng)的(de)磁場(chang)(chang)與主磁場(chang)(chang)相互作用(yong)產生(sheng)(sheng)電(dian)(dian)(dian)(dian)(dian)磁轉矩,使電(dian)(dian)(dian)(dian)(dian)機(ji)旋轉帶(dai)動(dong)負載。由于(yu)電(dian)(dian)(dian)(dian)(dian)刷(shua)和換(huan)(huan)向(xiang)器的(de)存在,有刷(shua)電(dian)(dian)(dian)(dian)(dian)機(ji)的(de)結(jie)構復雜,可靠性差,故(gu)障(zhang)多,維護工作量大,壽命短(duan),換(huan)(huan)向(xiang)火花(hua)易(yi)產生(sheng)(sheng)電(dian)(dian)(dian)(dian)(dian)磁干擾。有刷(shua)直流(liu)電(dian)(dian)(dian)(dian)(dian)機(ji)按(an)照結(jie)構類型、應用(yong)場(chang)(chang)景分(fen)為如(ru)下(xia)幾種(zhong)產品(pin):

1.有刷盤(pan)式(shi)(shi)繞(rao)組電(dian)(dian)(dian)機。有刷盤(pan)式(shi)(shi)繞(rao)組電(dian)(dian)(dian)機以稀土材(cai)料(liao)粘(zhan)結在一缸體上,漆包銅線繞(rao)成的盤(pan)式(shi)(shi)繞(rao)組置(zhi)于缸體之內,構(gou)成轉(zhuan)子。電(dian)(dian)(dian)機相(xiang)(xiang)位靠機械式(shi)(shi)換(huan)相(xiang)(xiang)器(qi)調(diao)整。機械式(shi)(shi)換(huan)相(xiang)(xiang)器(qi)是靠固(gu)定的炭制電(dian)(dian)(dian)刷與轉(zhuan)動的銅制換(huan)相(xiang)(xiang)面摩擦來調(diao)整電(dian)(dian)(dian)壓相(xiang)(xiang)位的。這(zhe)種電(dian)(dian)(dian)機在使(shi)用(yong)中電(dian)(dian)(dian)刷一直在磨損,電(dian)(dian)(dian)機的壽命很難超過2000h。同(tong)時(shi),由于電(dian)(dian)機的轉速(su)較高,必須采取兩(liang)級齒輪減(jian)速(su),這就帶來(lai)了兩(liang)個問題,一是噪聲(sheng)較大(da),二(er)是效率(lv)損失大(da),經減(jian)速(su)后的電(dian)(dian)機額(e)定效率(lv)往往只能達到68%~72%。而電動(dong)自行車所用的(de)蓄電池的(de)容量(liang)是(shi)有限的(de),一般(ban)就(jiu)是(shi)36V/12Ah的容量,如電機效率(lv)不高,將使電耗增加,影響續行里程。

2.有刷(shua)印(yin)制(zhi)(zhi)繞組電(dian)機。有刷(shua)印(yin)制(zhi)(zhi)繞組電(dian)機以(yi)印(yin)制(zhi)(zhi)銅(tong)箔板作(zuo)為(wei)繞組,電(dian)機重(zhong)量減輕(qing)了。由于這種電(dian)機全部是(shi)在自動生產線(xian)上生產的,工藝有可靠,從(cong)而使(shi)電(dian)機的壽命(ming)提高到(dao)3000h,噪聲(sheng)大(da)幅(fu)度(du)下降,效率提高到72%~76%。但這種電機(ji)有(you)“嗡嗡”的(de)高頻噪聲(sheng),靠齒(chi)輪減(jian)速后效(xiao)率仍不理(li)想,有(you)刷換(huan)相器的(de)使用使電機(ji)壽(shou)命無法再提高。

3.有刷壓制繞組電(dian)機(ji)。這(zhe)種電(dian)機(ji)通過將繞制好的銅(tong)線壓制成一種新型(xing)繞組,其效率(lv)可(ke)提高到(dao)74%~78%。這種電(dian)機仍然被(bei)較(jiao)多電(dian)動自行車廠家采用,但其(qi)存(cun)在(zai)的效率、噪聲、壽命缺(que)陷仍然是(shi)必須改進的問題。

4.輪(lun)轂式有(you)(you)齒(chi)輪(lun)傳(chuan)動(dong)的(de)(de)有(you)(you)刷(shua)(shua)(shua)(shua)(shua)直(zhi)(zhi)流電(dian)(dian)機(ji)(ji)(ji),由盤(pan)形電(dian)(dian)樞有(you)(you)刷(shua)(shua)(shua)(shua)(shua)電(dian)(dian)機(ji)(ji)(ji)和齒(chi)輪(lun)減(jian)(jian)速兼傳(chuan)動(dong)系統兩部分構成。盤(pan)形電(dian)(dian)樞是高速轉(zhuan)動(dong)的(de)(de)轉(zhuan)子。輪(lun)毅式有(you)(you)齒(chi)輪(lun)傳(chuan)動(dong)的(de)(de)有(you)(you)刷(shua)(shua)(shua)(shua)(shua)直(zhi)(zhi)流電(dian)(dian)機(ji)(ji)(ji)的(de)(de)構造。電(dian)(dian)機(ji)(ji)(ji)的(de)(de)轉(zhuan)矩通(tong)過軸傳(chuan)遞給級齒(chi)輪(lun),經齒(chi)輪(lun)減(jian)(jian)速帶(dai)動(dong)輪(lun)轂外殼轉(zhuan)動(dong);有(you)(you)刷(shua)(shua)(shua)(shua)(shua)有(you)(you)齒(chi)輪(lun)轂電(dian)(dian)機(ji)(ji)(ji)的(de)(de)盤(pan)形電(dian)(dian)樞是薄(bo)片(pian)形,體積(ji)很小(xiao),重量特輕,安裝方便(bian)。繞組編制好之后,用(yong)樹脂加玻(bo)璃纖維(wei)放進模內熱(re)壓成型(xing),在運(yun)(yun)行中由于電(dian)(dian)刷(shua)(shua)(shua)(shua)(shua)和換向器摩擦,又有(you)(you)齒(chi)輪(lun)嚙(nie)合減(jian)(jian)速,所以有(you)(you)刷(shua)(shua)(shua)(shua)(shua)電(dian)(dian)機(ji)(ji)(ji)的(de)(de)運(yun)(yun)行聲音比無(wu)刷(shua)(shua)(shua)(shua)(shua)電(dian)(dian)機(ji)(ji)(ji)聲音要大。

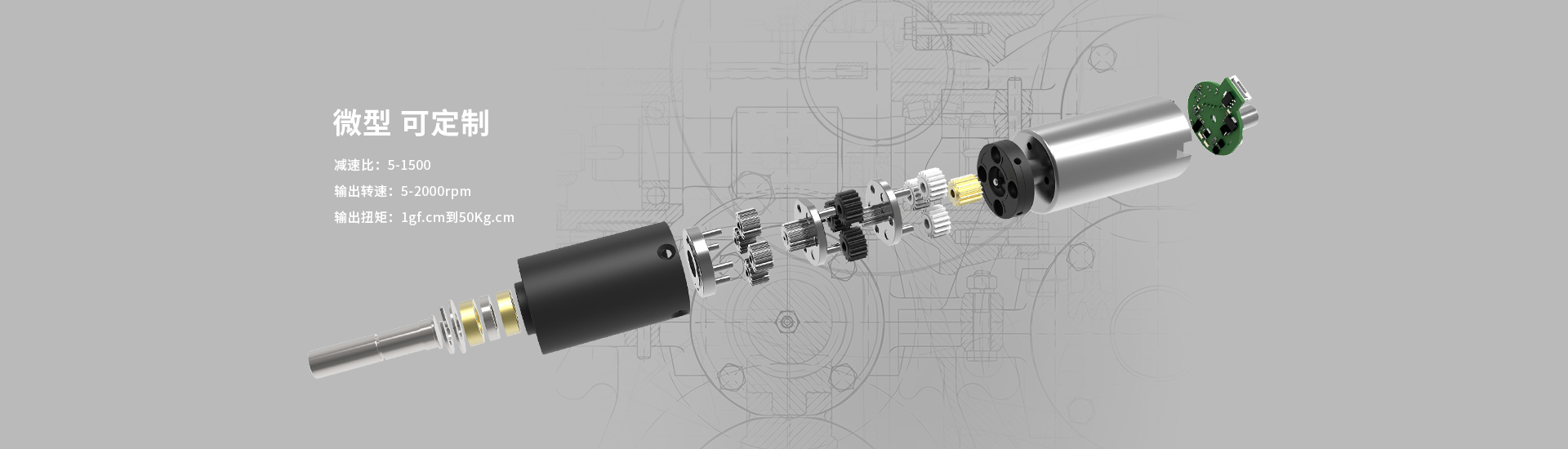

5.微型(xing)(xing)永(yong)(yong)磁(ci)體(ti)(ti)(ti)有刷直流(liu)電(dian)(dian)(dian)(dian)機,這種微型(xing)(xing)有刷直流(liu)電(dian)(dian)(dian)(dian)機是常見的(de)(de)有刷電(dian)(dian)(dian)(dian)機,采用永(yong)(yong)磁(ci)體(ti)(ti)(ti)產(chan)生磁(ci)場(chang)(chang),微型(xing)(xing)電(dian)(dian)(dian)(dian)機通的(de)(de)永(yong)(yong)磁(ci)體(ti)(ti)(ti)比繞組(zu)定子具有更高的(de)(de)效益,不(bu)過永(yong)(yong)磁(ci)體(ti)(ti)(ti)的(de)(de)磁(ci)性(xing)會(hui)隨著時(shi)間衰退(tui)(永(yong)(yong)磁(ci)體(ti)(ti)(ti)只是一(yi)個名字,并不(bu)是真正的(de)(de)永(yong)(yong)磁(ci))。有的(de)(de)永(yong)(yong)磁(ci)體(ti)(ti)(ti)微型(xing)(xing)直流(liu)電(dian)(dian)(dian)(dian)機還會(hui)加上(shang)繞組(zu),防止磁(ci)性(xing)丟失。由于定子磁(ci)場(chang)(chang)的(de)(de)恒定的(de)(de),所以永(yong)(yong)磁(ci)體(ti)(ti)(ti)有刷直流(liu)電(dian)(dian)(dian)(dian)機對電(dian)(dian)(dian)(dian)壓變(bian)化(hua)響應快。

6.并激(ji)(ji)有(you)刷(shua)直流電(dian)(dian)(dian)機(ji)(ji),微型(xing)電(dian)(dian)(dian)機(ji)(ji)的(de)勵磁線圈與(yu)電(dian)(dian)(dian)樞(shu)并聯,勵磁線圈中的(de)電(dian)(dian)(dian)流與(yu)電(dian)(dian)(dian)樞(shu)中的(de)電(dian)(dian)(dian)流相互(hu)獨立。因此,這類電(dian)(dian)(dian)機(ji)(ji)具有(you)卓越的(de)速度控(kong)制能力(li),并激(ji)(ji)有(you)刷(shua)直流電(dian)(dian)(dian)機(ji)(ji)不(bu)會出(chu)現(xian)磁性(xing)丟(diu)失的(de)現(xian)象,因此比永磁體電(dian)(dian)(dian)機(ji)(ji)更加可靠。

7.串激(ji)有(you)刷直(zhi)流電機,即勵(li)磁線(xian)圈與(yu)電樞(shu)(shu)串聯,定子和電樞(shu)(shu)中的電流均隨負載的增(zeng)(zeng)加而增(zeng)(zeng)加,因此這(zhe)類(lei)電機是大轉矩應用的理想(xiang)之選。但(dan)是對(dui)速度不能實現(xian)控制。

8.復激有刷直流電機(ji)這種(zhong)微電機(ji)是并(bing)(bing)激和(he)(he)串激電機(ji)的結合體,可產生(sheng)串激和(he)(he)并(bing)(bing)激兩種(zhong)磁場。綜合了并(bing)(bing)激和(he)(he)串激電機(ji)的性能,它(ta)具有大轉(zhuan)矩與(yu)的速度控制優(you)勢。

銷售電(dian)話:400-066-2287

郵(you)箱:sales@szzhaowei.net

傳真(zhen):0755-27323949

郵編:518000

地(di)址(zhi):深圳市寶安區(qu)燕(yan)(yan)羅街(jie)道燕(yan)(yan)川社區(qu)燕(yan)(yan)湖路62號(hao)