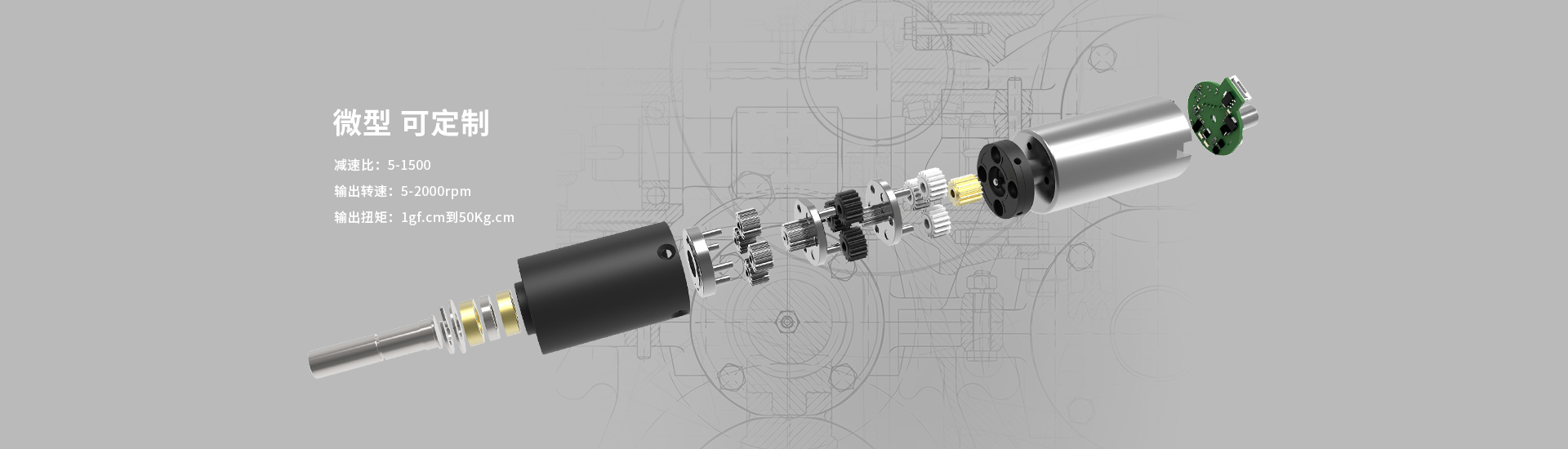

攝像頭(tou)微(wei)型刮水電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji)是一種小功(gong)率(lv)(lv)傳(chuan)動齒輪(lun)(lun)電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji),主要(yao)傳(chuan)動結(jie)構由(you)驅(qu)(qu)動電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji)、齒輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)(減(jian)速(su)(su)器)集(ji)成(cheng)(cheng)制(zhi)造組裝(zhuang)而(er)成(cheng)(cheng)的減(jian)速(su)(su)齒輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)傳(chuan)動設備;驅(qu)(qu)動電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji)可采用(yong)(yong)直流有(you)(you)刷電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji)、直流無刷電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji)、步進電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji)、空心杯(bei)電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji)、伺服電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji)作為驅(qu)(qu)動源,齒輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)可采用(yong)(yong)行星齒輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)、圓柱齒輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)、蝸輪(lun)(lun)蝸桿齒輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)、普通齒輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)作為減(jian)速(su)(su)器;攝像頭(tou)微(wei)型刮水電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji)通常(chang)采用(yong)(yong)定制(zhi)技術參(can)數開發而(er)成(cheng)(cheng),例如輸出功(gong)率(lv)(lv),電(dian)(dian)(dian)(dian)(dian)壓,減(jian)速(su)(su)比,輸出扭矩,傳(chuan)動精度(du),傳(chuan)動噪(zao)音,傳(chuan)動精度(du)等技術參(can)數是定制(zhi)開發而(er)成(cheng)(cheng);兆威(wei)機(ji)(ji)(ji)(ji)電(dian)(dian)(dian)(dian)(dian)股份有(you)(you)限公司致(zhi)力于研發、設計、制(zhi)造微(wei)型減(jian)速(su)(su)電(dian)(dian)(dian)(dian)(dian)機(ji)(ji)(ji)(ji),定制(zhi)技術參(can)數范圍,直徑規(gui)格在3.4mm-38mm之間,電壓(ya)在24V以下,輸出(chu)功率在50W以下,輸出轉速5rpm到1500rpm之間(jian),速比(bi)范圍2-2000之間,輸出力矩1gfNaN到50KgNaN之間微型傳(chuan)動(dong)齒輪箱減速系(xi)統。

項目名稱:物流攝像頭齒輪箱解決方案

項目背(bei)景:隨著(zhu)電(dian)(dian)子(zi)商(shang)務(wu)高(gao)速發展(zhan)(zhan)態(tai)勢,物(wu)流(liu)配(pei)送始終是(shi)電(dian)(dian)子(zi)商(shang)務(wu)發展(zhan)(zhan)的瓶(ping)頸(jing)。特別是(shi)物(wu)流(liu)配(pei)送體系還不夠完(wan)善、物(wu)流(liu)成 本居高不下、服務(wu)質量和效率低(di)下、配送(song)范圍(wei)不夠大、嚴重阻(zu)礙了電子(zi)商務(wu)的(de)發展(zhan)。

技術方案:兆威攝像頭齒輪箱方案用行業較小的8MM行星齒 輪(lun)箱,實現(xian)小體積大(da)力(li)矩的需求(qiu)。為(wei)實現(xian)攝像頭(tou)不同角(jiao)度和位置的 傳遞扭矩(ju)差異化,兆威設(she)計了多(duo)層可變換的傳動比機構,產品擁(yong)有(you) 二級、三級、四級傳動變化可根據攝像頭電(dian)機的設計(ji)需求(qiu)更換減速 比及(ji)調整齒輪(lun)箱的(de)輸入轉速及(ji)力(li)矩,即可實現(xian)各視覺系統(tong)中(zhong)的(de)攝像 頭翻(fan)轉、側邊(bian)攝(she)(she)像頭翻(fan)轉機頂端攝(she)(she)像頭旋(xuan)出、伸縮攝(she)(she)像頭等(deng)需(xu)求。

解決方案:除了解決攝(she)像(xiang)(xiang)頭(tou)多角度的智能(neng)旋(xuan)轉需求,兆威攝(she)像(xiang)(xiang)頭(tou)齒輪(lun)(lun)箱在研發設(she)計前期會(hui)利用的齒輪(lun)(lun)箱綜合設(she)計平臺,去(qu)實現(xian)漸開線行星齒輪(lun)(lun)系(xi)統、錐齒輪(lun)(lun)、面齒輪(lun)(lun)等(deng)機構的自動 化參(can)數設計,通(tong)過優化齒(chi)輪(lun)參(can)數,如變位(wei)系數、齒(chi)系數、壓力角、中(zhong)心距等,使(shi)嚙入沖(chong)擊(ji)(ji)(ji)速(su)度(du)降小,嚙出沖(chong)擊(ji)(ji)(ji)速(su)度(du)與(yu)嚙入沖(chong)擊(ji)(ji)(ji)速(su)度(du)的(de)比值處(chu)于某一數值范圍,減(jian)小或(huo)嚙合節圓(yuan)沖(chong)擊(ji)(ji)(ji)的(de)齒(chi)輪(lun)設計方法,解決產(chan)品(pin)在運轉靜音(微弱噪音)需求,降低(di)產(chan)品(pin)使(shi)用(yong)過程(cheng)中(zhong)的(de)噪音問(wen)題。