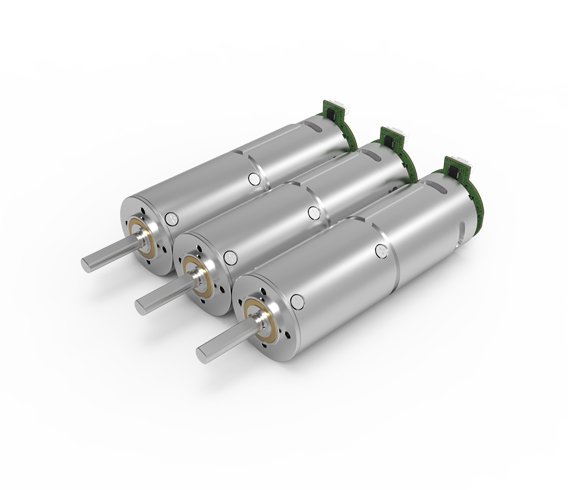

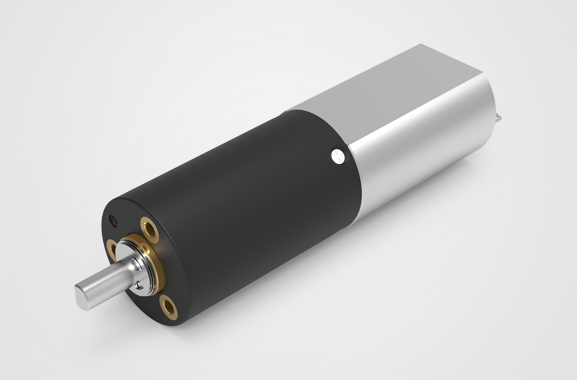

24伏直流電機帶減速機介紹

24伏直流電機帶減速機是(shi)一種小(xiao)(xiao)功(gong)率傳動(dong)(dong)電(dian)(dian)(dian)機(ji)(ji)(ji)齒(chi)輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)(xiang),也稱為(wei)24V直(zhi)(zhi)(zhi)流(liu)(liu)(liu)減(jian)速(su)電(dian)(dian)(dian)機(ji)(ji)(ji)是(shi)一種應(ying)用(yong)非常(chang)廣泛(fan)的減(jian)速(su)傳動(dong)(dong)設(she)(she)備(bei),直(zhi)(zhi)(zhi)徑(jing)規格小(xiao)(xiao),驅動(dong)(dong)電(dian)(dian)(dian)機(ji)(ji)(ji)和齒(chi)輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)(xiang)傳動(dong)(dong)結構可(ke)按照需求定制(zhi)開(kai)發而成,例(li)如,24伏(fu)直(zhi)(zhi)(zhi)流(liu)(liu)(liu)減(jian)速(su)電(dian)(dian)(dian)機(ji)(ji)(ji)的驅動(dong)(dong)電(dian)(dian)(dian)機(ji)(ji)(ji)可(ke)采用(yong)直(zhi)(zhi)(zhi)流(liu)(liu)(liu)有刷電(dian)(dian)(dian)機(ji)(ji)(ji)、直(zhi)(zhi)(zhi)流(liu)(liu)(liu)無刷電(dian)(dian)(dian)機(ji)(ji)(ji)作(zuo)為(wei)驅動(dong)(dong)源,減(jian)速(su)傳動(dong)(dong)齒(chi)輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)(xiang)可(ke)采用(yong)行星齒(chi)輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)(xiang)、圓(yuan)柱齒(chi)輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)(xiang)、平行齒(chi)輪(lun)(lun)箱(xiang)(xiang)(xiang)(xiang)(xiang)等;24V直(zhi)(zhi)(zhi)流(liu)(liu)(liu)減(jian)速(su)電(dian)(dian)(dian)機(ji)(ji)(ji)可(ke)應(ying)用(yong)在智能家(jia)居設(she)(she)備(bei)、自動(dong)(dong)工業化設(she)(she)備(bei)、智能機(ji)(ji)(ji)器人傳動(dong)(dong)模塊、智能汽車傳動(dong)(dong)模塊、消費電(dian)(dian)(dian)子產品(pin)等。

直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)減速(su)(su)(su)機(ji)原理:直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)減速(su)(su)(su)電(dian)(dian)機(ji)就(jiu)是調(diao)(diao)節直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)動機(ji)速(su)(su)(su)度的(de)設(she)備,上端和交(jiao)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)源(yuan)連接,下(xia)端和直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)動機(ji)連接,直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)調(diao)(diao)速(su)(su)(su)器將交(jiao)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)轉化成(cheng)兩路(lu)輸(shu)出直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)源(yuan),一(yi)路(lu)輸(shu)入給直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)機(ji)(推薦(jian):直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)減速(su)(su)(su)電(dian)(dian)機(ji))礪磁(定子),一(yi)路(lu)輸(shu)入給直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)機(ji)電(dian)(dian)樞(轉子),直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)調(diao)(diao)速(su)(su)(su)器通(tong)過控制電(dian)(dian)樞直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)壓來調(diao)(diao)節直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)動機(ji)轉速(su)(su)(su)。同時(shi)直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)動機(ji)給調(diao)(diao)速(su)(su)(su)器一(yi)個反饋電(dian)(dian)流(liu)(liu)(liu)(liu)(liu),調(diao)(diao)速(su)(su)(su)器根據反饋電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)來判斷直(zhi)(zhi)(zhi)流(liu)(liu)(liu)(liu)(liu)電(dian)(dian)機(ji)的(de)轉速(su)(su)(su)情況,必要時(shi)修正(zheng)電(dian)(dian)樞電(dian)(dian)壓輸(shu)出,以此(ci)來再次(ci)調(diao)(diao)節電(dian)(dian)機(ji)的(de)轉速(su)(su)(su)。

使用注意事項:

1.選(xuan)購(gou)直流減速(su)電機前確(que)定(ding)它的(de)使用(yong)途(tu)徑(jing),應用(yong)場景,列(lie)出環境(jing)要(yao)求、工(gong)作(zuo)溫度、背(bei)隙等因素;

2.首先確定功率(lv)需(xu)要考慮(lv)電流、電壓、轉速、減速比、傳(chuan)動比、扭矩、載(zai)荷(he)能力、噪音(yin)、傳(chuan)動效率(lv)、級數等。

3.接下來確(que)定直流(liu)減(jian)速電機輸(shu)出軸扭(niu)矩、安(an)轉(zhuan)方(fang)式(shi)、維護保(bao)養方(fang)式(shi);

4.其次(ci)確定直流減(jian)速電機(ji)輸入傳動軸轉(zhuan)速和減(jian)速比;

5.微型直流減速電機不要貯藏或運轉在高(gao)溫或潮濕環境(jing)中(zhong)(zhong),也(ye)不要放在腐蝕瓦斯中(zhong)(zhong);

6.使(shi)用(yong)前要確認電(dian)機電(dian)壓是(shi)否正確,電(dian)源電(dian)流是(shi)否足夠;

7.電機軸上裝(zhuang)配轉動件(jian)如齒(chi)輪(lun)、皮帶輪(lun)時,在(zai)壓入時不要異常的敲(qiao)打;

8.安(an)裝馬達時,注意螺(luo)絲釘(ding)是否過(guo)長(chang),杜絕過(guo)長(chang)的(de)螺(luo)絲壓碰電機里面的(de)零件;