行星減速機精度檢測方法

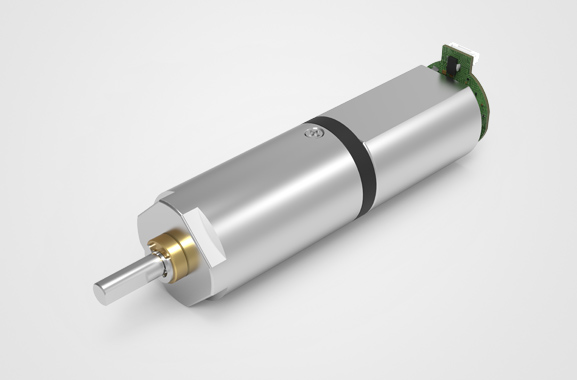

行星減速機也稱為行(xing)星(xing)齒輪箱,相(xiang)比較于普通(tong)減(jian)(jian)(jian)(jian)速(su)(su)機(ji),行(xing)星(xing)減(jian)(jian)(jian)(jian)速(su)(su)機(ji)具備精(jing)度高、壽命長(chang)、噪音(yin)低、扭矩大、減(jian)(jian)(jian)(jian)速(su)(su)范圍廣、傳動(dong)(dong)效率(lv)高等(deng)特(te)點,行(xing)星(xing)減(jian)(jian)(jian)(jian)速(su)(su)機(ji)是一種運用廣泛的減(jian)(jian)(jian)(jian)速(su)(su)傳動(dong)(dong)設(she)備,主要運用在冶金(jin)、采礦、有色金(jin)屬、能源、起重、碼頭(tou)、汽(qi)車(che)、家居、消費(fei)電子、通(tong)訊設(she)備、印刷等(deng)領域;運用在不(bu)同(tong)行(xing)業或(huo)者不(bu)同(tong)功(gong)率(lv)/參數、品牌(pai)的行(xing)星(xing)減(jian)(jian)(jian)(jian)速(su)(su)機(ji)的傳動(dong)(dong)精(jing)度也不(bu)一樣(yang),下面行(xing)星(xing)減(jian)(jian)(jian)(jian)速(su)(su)機(ji)精(jing)度檢測(ce)方法(fa)。

行星減速機精度:

行星減(jian)速(su)(su)(su)機(ji)(ji)(ji)的精(jing)度單位為(wei)弧分 [Arcmin]:一(yi)(yi)度分為(wei)60 弧分(=60 Arcmin=60′).如回(hui)(hui)程間(jian)隙標為(wei)1 arcmin 時(shi),意思是說(shuo)減(jian)速(su)(su)(su)機(ji)(ji)(ji)轉一(yi)(yi)圈,輸(shu)(shu)出(chu)端(duan)(duan)(duan)的角(jiao)偏(pian)差為(wei)1/60°。在實際(ji)應用(yong)中,這個(ge)角(jiao)偏(pian)差與(yu)軸直(zhi)徑有關b=2·π·r·a°/360°。就(jiu)是說(shuo),輸(shu)(shu)出(chu)端(duan)(duan)(duan)半(ban)徑為(wei)500mm時(shi),齒輪箱精(jing)度為(wei)jt=3′時(shi),即a°=3/60,減(jian)速(su)(su)(su)機(ji)(ji)(ji)轉一(yi)(yi)圈的偏(pian)差為(wei)b=0.44mm。 精(jing)度也稱為(wei)回(hui)(hui)程間(jian)隙,行星減(jian)速(su)(su)(su)機(ji)(ji)(ji)的回(hui)(hui)程間(jian)隙是將輸(shu)(shu)出(chu)端(duan)(duan)(duan)固定(ding),輸(shu)(shu)入端(duan)(duan)(duan)順時(shi)針(zhen)和逆時(shi)針(zhen)方向旋(xuan)轉,使(shi)輸(shu)(shu)出(chu)端(duan)(duan)(duan)產生額定(ding)扭矩(ju)的±2%扭矩(ju)時(shi),減(jian)速(su)(su)(su)機(ji)(ji)(ji)輸(shu)(shu)入端(duan)(duan)(duan)有一(yi)(yi)個(ge)微(wei)小(xiao)的角(jiao)位移,此(ci)角(jiao)位移即為(wei)回(hui)(hui)程間(jian)隙。?

精度測量方法:

1.靜態(tai)測(ce)量:是指在(zai)靜止(zhi)狀態(tai)下,從精密(mi)減速器回(hui)(hui)差的定義入(ru)手,測(ce)量運動方向改變(bian)時輸出端(duan)在(zai)轉角上(shang)的滯后(hou)量,主要有多(duo)面(mian)體(ti)法和滯回(hui)(hui)曲線法。

2.多面(mian)(mian)體法:采(cai)用測(ce)(ce)角(jiao)(jiao)裝(zhuang)置、自準平行(xing)光(guang)(guang)管、多面(mian)(mian)棱(leng)體等(deng)對精密減速器的回差進行(xing)測(ce)(ce)量(liang)(liang),測(ce)(ce)量(liang)(liang)時(shi)將測(ce)(ce)角(jiao)(jiao)裝(zhuang)置安裝(zhuang)在(zai)輸入軸,并通過采(cai)集卡采(cai)集輸入軸的轉角(jiao)(jiao),多面(mian)(mian)棱(leng)體固定(ding)在(zai)輸出軸,調整(zheng)自準平行(xing)光(guang)(guang)管垂直多面(mian)(mian)體的一個面(mian)(mian),并對多面(mian)(mian)體進行(xing)觀測(ce)(ce)和定(ding)位。當輸入軸正轉改為反(fan)轉時(shi),兩極限(xian)轉角(jiao)(jiao)之差除以傳動比即(ji)為輸出軸回差。

3.動(dong)態測(ce)量:是指在(zai)接近精(jing)密減速器(qi)的運行狀(zhuang)態下對(dui)精(jing)密減速器(qi)回差進行的動(dong)態連(lian)續測(ce)量,主要(yao)測(ce)量方(fang)法為雙(shuang)向傳動(dong)誤差法。

4.滯(zhi)回(hui)(hui)(hui)曲(qu)線(xian)法(fa):由于內(nei)部間隙(xi)(xi)(xi)、彈性(xing)變(bian)形(xing)、摩(mo)(mo)擦(ca)等的耦合作用(yong),滯(zhi)回(hui)(hui)(hui)特(te)性(xing)在(zai)精密(mi)(mi)減(jian)(jian)(jian)速(su)器(qi)(qi)中普遍存在(zai),通常表(biao)現(xian)為(wei)(wei)系統在(zai)正反向行(xing)程上所對應(ying)輸出的不一(yi)致現(xian)象,而減(jian)(jian)(jian)速(su)器(qi)(qi)、齒輪副傳動(dong)中表(biao)現(xian)出的間隙(xi)(xi)(xi),可以看做(zuo)是滯(zhi)回(hui)(hui)(hui)現(xian)象的特(te)例。目(mu)前(qian),研究者主要從運動(dong)控制的角度(du),對精密(mi)(mi)減(jian)(jian)(jian)速(su)器(qi)(qi)的滯(zhi)回(hui)(hui)(hui)特(te)性(xing)進行(xing)分析(xi)建模。工業領域(yu)通常采用(yong)滯(zhi)回(hui)(hui)(hui)曲(qu)線(xian)法(fa)測(ce)量精密(mi)(mi)減(jian)(jian)(jian)速(su)器(qi)(qi)的回(hui)(hui)(hui)差(cha)(cha),并(bing)將精密(mi)(mi)減(jian)(jian)(jian)速(su)器(qi)(qi)的幾何回(hui)(hui)(hui)差(cha)(cha)定義為(wei)(wei):施(shi)加(jia)±3%額定扭(niu)矩(ju)以克服內(nei)部摩(mo)(mo)擦(ca)和(he)(he)油膜阻力,并(bing)且各部件接觸良(liang)好的情況下,由傳動(dong)鏈(lian)中的齒側間隙(xi)(xi)(xi)、軸承間隙(xi)(xi)(xi)等幾何因素引起的輸出軸轉角值,又稱為(wei)(wei)空程回(hui)(hui)(hui)差(cha)(cha)或間隙(xi)(xi)(xi)回(hui)(hui)(hui)差(cha)(cha)。測(ce)量時,將精密(mi)(mi)減(jian)(jian)(jian)速(su)器(qi)(qi)的一(yi)端鎖緊,另一(yi)端正向梯度(du)加(jia)載(zai)至額定扭(niu)矩(ju),然后梯度(du)卸載(zai);以同樣(yang)的方法(fa),做(zuo)反向梯度(du)加(jia)載(zai)、卸載(zai),實時采集扭(niu)矩(ju)和(he)(he)扭(niu)轉角信號,并(bing)繪制滯(zhi)回(hui)(hui)(hui)曲(qu)線(xian)。