微型行星減速機參數詳解

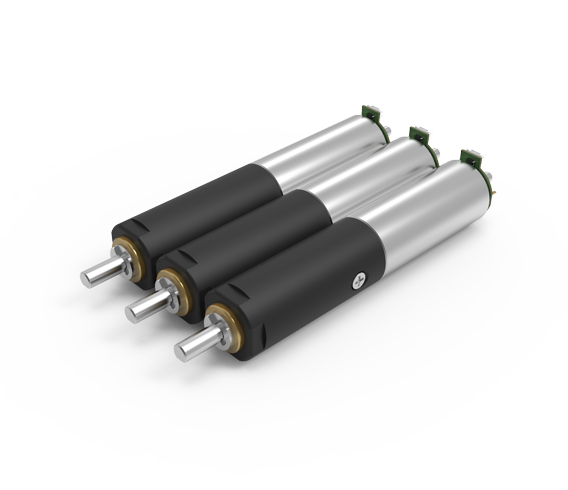

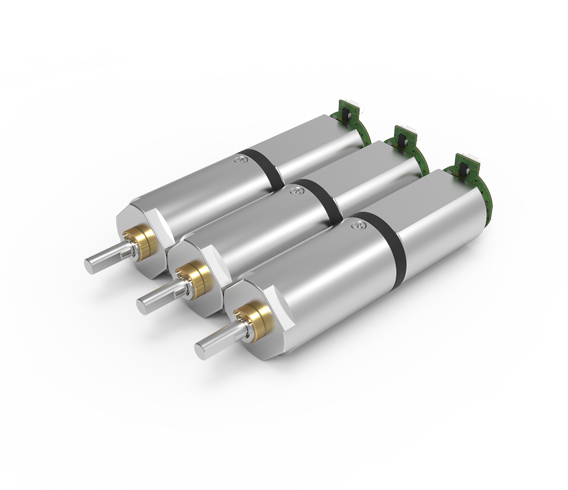

微型行星減速機是(shi)一種運(yun)用(yong)廣(guang)泛(fan)的(de)(de)減(jian)(jian)速(su)設(she)備,相(xiang)比較普通減(jian)(jian)速(su)機(ji)(ji)(ji)、齒輪減(jian)(jian)速(su)機(ji)(ji)(ji)的(de)(de)傳(chuan)動效(xiao)率、減(jian)(jian)速(su)效(xiao)率、傳(chuan)動精度要高很多;微(wei)型行星減(jian)(jian)速(su)機(ji)(ji)(ji)的(de)(de)常用(yong)規格在38mm以下,廣(guang)泛(fan)運(yun)用(yong)在智(zhi)能家居、消費電子產(chan)品、智(zhi)能汽(qi)車(che)、智(zhi)慧(hui)醫療、5G通訊(xun)、智(zhi)能機(ji)(ji)(ji)器人等領(ling)域(yu)(yu),不(bu)同的(de)(de)運(yun)用(yong)領(ling)域(yu)(yu)、產(chan)品設(she)備采用(yong)不(bu)同型號、規格、參(can)數的(de)(de)微(wei)型行星減(jian)(jian)速(su)機(ji)(ji)(ji)。

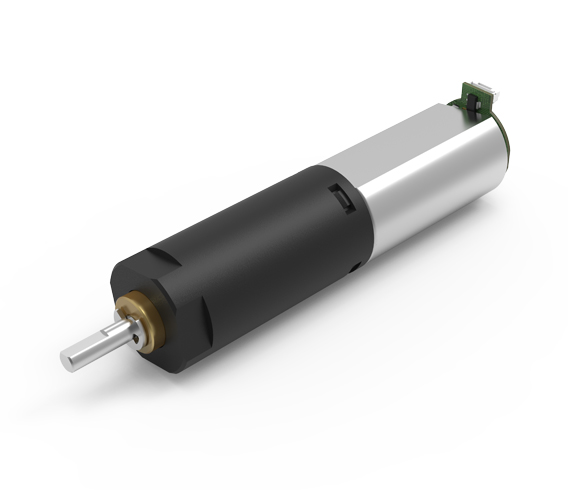

行(xing)(xing)星(xing)齒(chi)輪級(ji)(ji)數(shu):行(xing)(xing)星(xing)齒(chi)輪的(de)套(tao)數(shu)。由于一套(tao)行(xing)(xing)星(xing)齒(chi)輪無(wu)法滿(man)足較大(da)的(de)傳(chuan)動(dong)比,有(you)(you)時需要2套(tao)或者3套(tao)來滿(man)足用(yong)戶較大(da)的(de)傳(chuan)動(dong)比的(de)要求.由于增加了行(xing)(xing)星(xing)齒(chi)輪的(de)數(shu)量,所以2級(ji)(ji)或3級(ji)(ji)減速機(ji)的(de)長度會(hui)有(you)(you)所增加,效率會(hui)有(you)(you)所下降(jiang)。

回程間(jian)(jian)隙:將輸(shu)(shu)(shu)出端固定,輸(shu)(shu)(shu)入(ru)(ru)端順(shun)時(shi)針和逆時(shi)針方向旋轉,使輸(shu)(shu)(shu)入(ru)(ru)端產(chan)生(sheng)額定扭(niu)矩+-2%扭(niu)矩時(shi),減速(su)機輸(shu)(shu)(shu)入(ru)(ru)端有一(yi)個微小的角(jiao)位(wei)移,此角(jiao)位(wei)移就(jiu)是回程間(jian)(jian)隙.單位(wei)是”分”,就(jiu)是一(yi)度的六十分之一(yi).也有人稱之為背隙,這就(jiu)是傳(chuan)動(dong)精度。

減(jian)(jian)(jian)(jian)速(su)(su)比(bi)(bi)(bi):減(jian)(jian)(jian)(jian)速(su)(su)機的(de)(de)傳動減(jian)(jian)(jian)(jian)速(su)(su)比(bi)(bi)(bi)的(de)(de)表示方(fang)法(fa)(fa)(fa)是(shi)以1為(wei)(wei)分(fen)母(mu),用(yong)“:”連(lian)接的(de)(de)輸(shu)(shu)入轉(zhuan)(zhuan)速(su)(su)和輸(shu)(shu)出轉(zhuan)(zhuan)速(su)(su)的(de)(de)比(bi)(bi)(bi)值,如(ru)輸(shu)(shu)入轉(zhuan)(zhuan)速(su)(su)為(wei)(wei)1500r/min,輸(shu)(shu)出轉(zhuan)(zhuan)速(su)(su)為(wei)(wei)25r/min,那么其減(jian)(jian)(jian)(jian)速(su)(su)比(bi)(bi)(bi)則為(wei)(wei):i=60:1。一(yi)般的(de)(de)減(jian)(jian)(jian)(jian)速(su)(su)機構減(jian)(jian)(jian)(jian)速(su)(su)比(bi)(bi)(bi)標注都(dou)是(shi)實(shi)際減(jian)(jian)(jian)(jian)速(su)(su)比(bi)(bi)(bi),但有些特殊(shu)減(jian)(jian)(jian)(jian)速(su)(su)機如(ru)擺(bai)線減(jian)(jian)(jian)(jian)速(su)(su)機或者諧波(bo)減(jian)(jian)(jian)(jian)速(su)(su)機等有時(shi)候用(yong)舍入法(fa)(fa)(fa)取整,且不要分(fen)母(mu),如(ru)實(shi)際減(jian)(jian)(jian)(jian)速(su)(su)比(bi)(bi)(bi)可(ke)能為(wei)(wei)28.13,而(er)標注時(shi)一(yi)般標注28。減(jian)(jian)(jian)(jian)速(su)(su)比(bi)(bi)(bi)計算方(fang)法(fa)(fa)(fa):減(jian)(jian)(jian)(jian)速(su)(su)比(bi)(bi)(bi)=輸(shu)(shu)入轉(zhuan)(zhuan)速(su)(su)÷輸(shu)(shu)出轉(zhuan)(zhuan)速(su)(su);

輸(shu)(shu)出扭(niu)(niu)矩:行星減速(su)(su)機(ji)由多套行星齒(chi)輪系組合而成,行星齒(chi)輪系套(級(ji))數越(yue)多,減速(su)(su)比越(yue)多,輸(shu)(shu)出扭(niu)(niu)矩越(yue)大,反之越(yue)小;輸(shu)(shu)出扭(niu)(niu)矩計算公式:扭(niu)(niu)矩=9550×電機(ji)功(gong)率(lv)×速(su)(su)比×使用效率(lv)/電機(ji)輸(shu)(shu)入(ru)轉數功(gong)率(lv)(W)=扭(niu)(niu)矩(nm)*角速(su)(su)度。

傳動噪(zao)音:齒(chi)(chi)形誤差(cha)小(xiao)、齒(chi)(chi)面(mian)(mian)粗糙度小(xiao)的(de)齒(chi)(chi)輪(lun),在(zai)相同試(shi)(shi)驗條件下,其(qi)噪(zao)聲(sheng)(sheng)比普(pu)通(tong)齒(chi)(chi)輪(lun)要小(xiao)10dB。齒(chi)(chi)距(ju)誤差(cha)小(xiao)的(de)齒(chi)(chi)輪(lun),在(zai)相同試(shi)(shi)驗條件下,其(qi)噪(zao)聲(sheng)(sheng)級比普(pu)通(tong)齒(chi)(chi)輪(lun)要小(xiao)6~12dB。但如果有(you)齒(chi)(chi)距(ju)誤差(cha)存在(zai),負載對齒(chi)(chi)輪(lun)噪(zao)聲(sheng)(sheng)的(de)影響將(jiang)會減少。齒(chi)(chi)向誤差(cha)將(jiang)導致傳動功率不是全齒(chi)(chi)寬傳遞,接觸區轉向齒(chi)(chi)的(de)這端面(mian)(mian)或(huo)那個(ge)端面(mian)(mian),因局部(bu)受力增大輪(lun)齒(chi)(chi)撓曲,導致噪(zao)聲(sheng)(sheng)級提高。