直流無刷電機的優越性

直流無刷電機具有響應快(kuai)速(su)(su)(su)、較大的起動轉(zhuan)矩(ju)、從(cong)零轉(zhuan)速(su)(su)(su)至額定(ding)轉(zhuan)速(su)(su)(su)具備可提供額定(ding)轉(zhuan)矩(ju)的性能(neng),但直(zhi)(zhi)流電(dian)(dian)(dian)(dian)機(ji)的特(te)點也正是(shi)它的缺點,因為直(zhi)(zhi)流電(dian)(dian)(dian)(dian)機(ji)要產生(sheng)額定(ding)負載下恒定(ding)轉(zhuan)矩(ju)的性能(neng),這就(jiu)要藉由(you)碳(tan)刷及整(zheng)流子。碳(tan)刷及整(zheng)流子在電(dian)(dian)(dian)(dian)機(ji)轉(zhuan)動時會(hui)產生(sheng)火花、碳(tan)粉因此除(chu)了會(hui)造成組件損壞之外,使用(yong)場(chang)合(he)也受到(dao)限制。交流電(dian)(dian)(dian)(dian)機(ji)沒有碳(tan)刷及整(zheng)流子,免維護、堅(jian)固、應用(yong)廣(guang),但特(te)性上若(ruo)要達(da)到(dao)相當(dang)(dang)于直(zhi)(zhi)流電(dian)(dian)(dian)(dian)機(ji)的性能(neng)須用(yong)復雜(za)控制技術才能(neng)達(da)到(dao)。現(xian)(xian)今(jin)半導體發展迅速(su)(su)(su)功率組件切(qie)換頻(pin)率加快(kuai)許多,提升傳動電(dian)(dian)(dian)(dian)機(ji)的性能(neng)。微(wei)處(chu)理機(ji)速(su)(su)(su)度亦越(yue)(yue)來越(yue)(yue)快(kuai),可實(shi)現(xian)(xian)將交流電(dian)(dian)(dian)(dian)機(ji)控制置于一旋(xuan)轉(zhuan)的兩(liang)軸(zhou)直(zhi)(zhi)交坐標系統中,適當(dang)(dang)控制交流電(dian)(dian)(dian)(dian)機(ji)在兩(liang)軸(zhou)電(dian)(dian)(dian)(dian)流分量,達(da)到(dao)類(lei)似(si)直(zhi)(zhi)流電(dian)(dian)(dian)(dian)機(ji)控制并有與(yu)直(zhi)(zhi)流電(dian)(dian)(dian)(dian)機(ji)相當(dang)(dang)的性能(neng)。

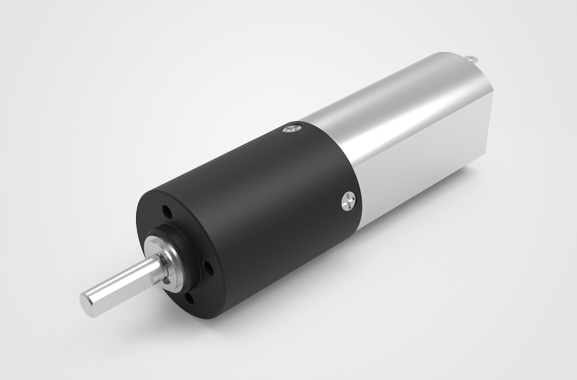

此外已有很多微處理機將控制電機必需的功能做在芯片中,而且體積越來越小;像模擬/數字轉換器(推薦:兆威機電減速器),脈(mo)沖寬度(du)調(diao)制等。直流無刷(shua)減速電(dian)機(ji)即是以電(dian)子(zi)方式控制交(jiao)流電(dian)機(ji)換相(xiang),得(de)到類似直流電(dian)機(ji)特性又(you)沒有直流電(dian)機(ji)機(ji)構(gou)上缺失(shi)的(de)一種應用。