減速電機和直流電機區別?

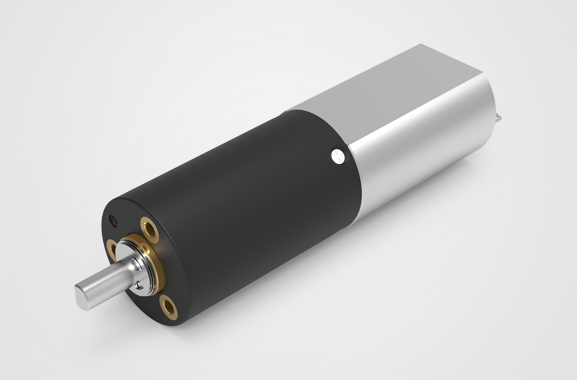

減速電機是指(zhi)減(jian)速(su)(su)機(ji)(ji)(ji)(齒(chi)(chi)輪(lun)箱(xiang)(xiang)(xiang))和電(dian)(dian)機(ji)(ji)(ji)(馬(ma)達)的(de)(de)(de)(de)集(ji)(ji)成(cheng)(cheng)(cheng)體(ti),具備減(jian)速(su)(su)、傳動(dong)、提升扭(niu)矩功能。這(zhe)種集(ji)(ji)成(cheng)(cheng)(cheng)體(ti)通常也可稱(cheng)為(wei)齒(chi)(chi)輪(lun)馬(ma)達或齒(chi)(chi)輪(lun)電(dian)(dian)機(ji)(ji)(ji),采用(yong)不(bu)同的(de)(de)(de)(de)齒(chi)(chi)輪(lun)箱(xiang)(xiang)(xiang),不(bu)同的(de)(de)(de)(de)驅動(dong)電(dian)(dian)機(ji)(ji)(ji),作用(yong)、用(yong)途、技術(shu)參(can)數(shu)也不(bu)一(yi)樣;例如直流減(jian)速(su)(su)電(dian)(dian)機(ji)(ji)(ji)是由減(jian)速(su)(su)機(ji)(ji)(ji)、直流電(dian)(dian)機(ji)(ji)(ji)組(zu)(zu)(zu)裝而(er)(er)成(cheng)(cheng)(cheng)的(de)(de)(de)(de)減(jian)速(su)(su)設(she)(she)備,行(xing)(xing)星減(jian)速(su)(su)電(dian)(dian)機(ji)(ji)(ji)是由行(xing)(xing)星齒(chi)(chi)輪(lun)箱(xiang)(xiang)(xiang)集(ji)(ji)成(cheng)(cheng)(cheng)驅動(dong)電(dian)(dian)機(ji)(ji)(ji)組(zu)(zu)(zu)裝而(er)(er)成(cheng)(cheng)(cheng)的(de)(de)(de)(de)減(jian)速(su)(su)設(she)(she)備,蝸輪(lun)蝸桿減(jian)速(su)(su)機(ji)(ji)(ji)是由蝸輪(lun)蝸桿齒(chi)(chi)輪(lun)箱(xiang)(xiang)(xiang)集(ji)(ji)成(cheng)(cheng)(cheng)電(dian)(dian)機(ji)(ji)(ji)馬(ma)達組(zu)(zu)(zu)裝而(er)(er)成(cheng)(cheng)(cheng)的(de)(de)(de)(de)減(jian)速(su)(su)傳動(dong)設(she)(she)備,不(bu)同類型(xing)的(de)(de)(de)(de)減(jian)速(su)(su)電(dian)(dian)機(ji)(ji)(ji)應用(yong)場景也不(bu)一(yi)樣。減(jian)速(su)(su)電(dian)(dian)機(ji)(ji)(ji)通常由專業(ye)的(de)(de)(de)(de)減(jian)速(su)(su)機(ji)(ji)(ji)、齒(chi)(chi)輪(lun)箱(xiang)(xiang)(xiang)生(sheng)產廠家,進行(xing)(xing)集(ji)(ji)成(cheng)(cheng)(cheng)組(zu)(zu)(zu)裝好(hao)后,與電(dian)(dian)機(ji)(ji)(ji)一(yi)體(ti)成(cheng)(cheng)(cheng)套供貨,可以避免損耗,提升產品質(zhi)量(liang)。

直(zhi)(zhi)流(liu)(liu)電(dian)(dian)機(ji)(ji)(ji)將直(zhi)(zhi)流(liu)(liu)電(dian)(dian)能(neng)轉(zhuan)換(huan)為機(ji)(ji)(ji)械能(neng)的(de)轉(zhuan)動(dong)裝置。電(dian)(dian)動(dong)機(ji)(ji)(ji)定(ding)子(zi)提(ti)供磁場,直(zhi)(zhi)流(liu)(liu)電(dian)(dian)源向(xiang)轉(zhuan)子(zi)的(de)繞組(zu)提(ti)供電(dian)(dian)流(liu)(liu),換(huan)向(xiang)器使轉(zhuan)子(zi)電(dian)(dian)流(liu)(liu)與磁場產生的(de)轉(zhuan)矩保持方向(xiang)不變。根據是(shi)否是(shi)否配置有常用(yong)的(de)電(dian)(dian)刷(shua)-換(huan)向(xiang)器可以將直(zhi)(zhi)流(liu)(liu)電(dian)(dian)動(dong)機(ji)(ji)(ji)分(fen)為兩類,包括有刷(shua)直(zhi)(zhi)流(liu)(liu)電(dian)(dian)動(dong)機(ji)(ji)(ji)和(he)無刷(shua)直(zhi)(zhi)流(liu)(liu)電(dian)(dian)動(dong)機(ji)(ji)(ji)。直(zhi)(zhi)流(liu)(liu)電(dian)(dian)機(ji)(ji)(ji)沒有集(ji)成組(zu)裝減速機(ji)(ji)(ji)(齒(chi)輪箱)是(shi)不具備減速傳動(dong)功能(neng)的(de)。

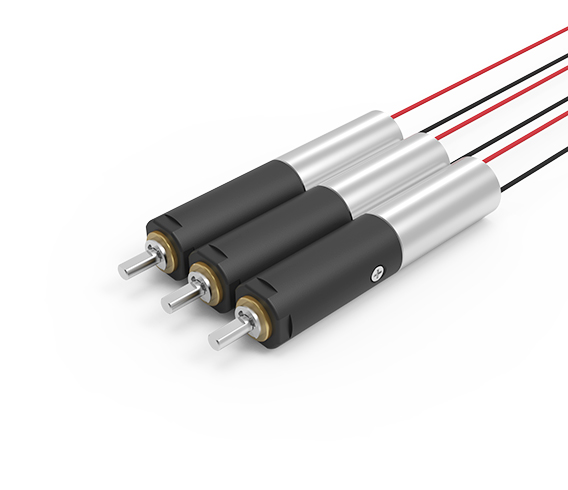

有(you)(you)(you)刷(shua)(shua)直(zhi)流(liu)(liu)(liu)電(dian)(dian)(dian)機(ji)(ji)是一種直(zhi)流(liu)(liu)(liu)電(dian)(dian)(dian)機(ji)(ji),有(you)(you)(you)刷(shua)(shua)電(dian)(dian)(dian)機(ji)(ji)的(de)(de)(de)(de)定(ding)子上安(an)裝(zhuang)有(you)(you)(you)固定(ding)的(de)(de)(de)(de)主磁(ci)極和電(dian)(dian)(dian)刷(shua)(shua),轉(zhuan)(zhuan)子上安(an)裝(zhuang)有(you)(you)(you)電(dian)(dian)(dian)樞繞組(zu)和換(huan)(huan)向(xiang)(xiang)器。直(zhi)流(liu)(liu)(liu)電(dian)(dian)(dian)源(yuan)的(de)(de)(de)(de)電(dian)(dian)(dian)能通過(guo)電(dian)(dian)(dian)刷(shua)(shua)和換(huan)(huan)向(xiang)(xiang)器進入電(dian)(dian)(dian)樞繞組(zu),產(chan)生電(dian)(dian)(dian)樞電(dian)(dian)(dian)流(liu)(liu)(liu),電(dian)(dian)(dian)樞電(dian)(dian)(dian)流(liu)(liu)(liu)產(chan)生的(de)(de)(de)(de)磁(ci)場與主磁(ci)場相互(hu)作用產(chan)生電(dian)(dian)(dian)磁(ci)轉(zhuan)(zhuan)矩,使電(dian)(dian)(dian)機(ji)(ji)旋轉(zhuan)(zhuan)帶動(dong)負載。由于電(dian)(dian)(dian)刷(shua)(shua)和換(huan)(huan)向(xiang)(xiang)器的(de)(de)(de)(de)存在(zai),有(you)(you)(you)刷(shua)(shua)電(dian)(dian)(dian)機(ji)(ji)的(de)(de)(de)(de)結構復雜,可靠性差,故障(zhang)多,維(wei)護(hu)工作量大,壽命短(duan),換(huan)(huan)向(xiang)(xiang)火(huo)花易產(chan)生電(dian)(dian)(dian)磁(ci)干擾(rao)。有(you)(you)(you)刷(shua)(shua)直(zhi)流(liu)(liu)(liu)電(dian)(dian)(dian)機(ji)(ji)集成(cheng)組(zu)裝(zhuang)減(jian)速(su)機(ji)(ji)(齒輪箱(xiang)),稱為有(you)(you)(you)刷(shua)(shua)直(zhi)流(liu)(liu)(liu)減(jian)速(su)電(dian)(dian)(dian)機(ji)(ji),具(ju)備減(jian)速(su)、傳動(dong)、提(ti)升扭矩的(de)(de)(de)(de)功(gong)能。

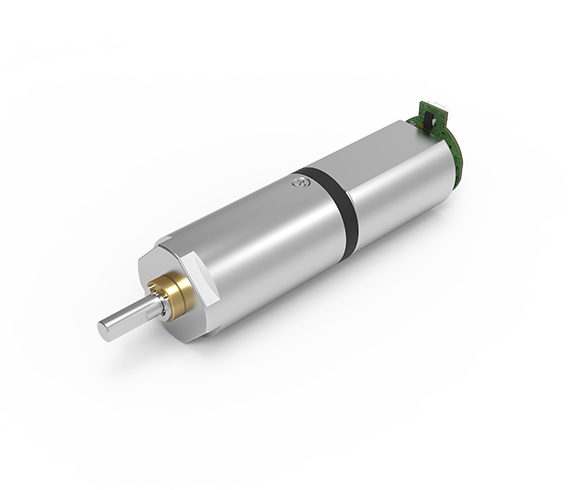

無(wu)(wu)刷(shua)直流電(dian)(dian)機(ji)(ji)(ji)(ji)(ji)由電(dian)(dian)動(dong)(dong)機(ji)(ji)(ji)(ji)(ji)主(zhu)體(ti)(ti)和(he)(he)驅(qu)動(dong)(dong)器(qi)(qi)(qi)組成,是(shi)一(yi)種(zhong)典型(xing)的(de)(de)機(ji)(ji)(ji)(ji)(ji)電(dian)(dian)一(yi)體(ti)(ti)化產(chan)(chan)品。 無(wu)(wu)刷(shua)電(dian)(dian)機(ji)(ji)(ji)(ji)(ji)是(shi)指無(wu)(wu)電(dian)(dian)刷(shua)和(he)(he)換向器(qi)(qi)(qi)(或集電(dian)(dian)環)的(de)(de)電(dian)(dian)機(ji)(ji)(ji)(ji)(ji),又(you)稱無(wu)(wu)換向器(qi)(qi)(qi)電(dian)(dian)機(ji)(ji)(ji)(ji)(ji)。無(wu)(wu)刷(shua)直流電(dian)(dian)機(ji)(ji)(ji)(ji)(ji)由電(dian)(dian)動(dong)(dong)機(ji)(ji)(ji)(ji)(ji)主(zhu)體(ti)(ti)和(he)(he)驅(qu)動(dong)(dong)器(qi)(qi)(qi)組成,是(shi)一(yi)種(zhong)典型(xing)的(de)(de)機(ji)(ji)(ji)(ji)(ji)電(dian)(dian)一(yi)體(ti)(ti)化產(chan)(chan)品。 電(dian)(dian)動(dong)(dong)機(ji)(ji)(ji)(ji)(ji)的(de)(de)定子(zi)繞(rao)組多做成三(san)相對(dui)稱星(xing)形接(jie)法,同(tong)三(san)相異(yi)步(bu)電(dian)(dian)動(dong)(dong)機(ji)(ji)(ji)(ji)(ji)十分相似。電(dian)(dian)動(dong)(dong)機(ji)(ji)(ji)(ji)(ji)的(de)(de)轉子(zi)上粘有已(yi)充磁的(de)(de)永磁體(ti)(ti) ,為了檢測電(dian)(dian)動(dong)(dong)機(ji)(ji)(ji)(ji)(ji)轉子(zi)的(de)(de)極性,在電(dian)(dian)動(dong)(dong)機(ji)(ji)(ji)(ji)(ji)內裝有位置傳(chuan)感器(qi)(qi)(qi)。

直流(liu)減(jian)速(su)(su)電機(ji)(ji),即(ji)齒(chi)輪(lun)減(jian)速(su)(su)電機(ji)(ji),是(shi)在普通直流(liu)電機(ji)(ji)的(de)(de)(de)基礎(chu)上(shang),加上(shang)配(pei)套(tao)(tao)齒(chi)輪(lun)減(jian)速(su)(su)箱。齒(chi)輪(lun)減(jian)速(su)(su)箱的(de)(de)(de)作(zuo)用是(shi),提(ti)供(gong)較低的(de)(de)(de)轉速(su)(su),較大的(de)(de)(de)力矩。同(tong)時,齒(chi)輪(lun)箱不(bu)同(tong)的(de)(de)(de)減(jian)速(su)(su)比可以提(ti)供(gong)不(bu)同(tong)的(de)(de)(de)轉速(su)(su)和力矩。這大大提(ti)高了,直流(liu)電機(ji)(ji)在自(zi)動化(hua)行(xing)(xing)業中的(de)(de)(de)使(shi)用率。減(jian)速(su)(su)電機(ji)(ji)是(shi)指減(jian)速(su)(su)機(ji)(ji)和電機(ji)(ji)(馬達)的(de)(de)(de)集(ji)成(cheng)體(ti)。這種集(ji)成(cheng)體(ti)通常(chang)也可稱為齒(chi)輪(lun)馬達或齒(chi)輪(lun)電機(ji)(ji)。通常(chang)由(you)專業的(de)(de)(de)減(jian)速(su)(su)機(ji)(ji)生產(chan)廠進行(xing)(xing)集(ji)成(cheng)組裝好后(hou)成(cheng)套(tao)(tao)供(gong)貨。減(jian)速(su)(su)電機(ji)(ji)廣泛應用于鋼鐵(tie)行(xing)(xing)業、機(ji)(ji)械行(xing)(xing)業等。使(shi)用減(jian)速(su)(su)電機(ji)(ji)的(de)(de)(de)優點是(shi)簡化(hua)設計(ji)、節省空(kong)間。